فيما يلي تفصيل لـ قائمة التحقق من عملية تجميع مكيف الهواء الدقيق:

1. تركيب الرفوف

نبدأ بالمحاذاة الهيكلية وجودة السطح:

- يتم محاذاة القاعدة والإطار العلوي والأعمدة الرأسية على نفس المستوى مع وجود تفاوت قطري في حدود 3 مم.

- يجب أن يكون سطح الرف موحد اللون وخاليًا من الخدوش أو الانبعاجات أو بقع الزيت أو عيوب الطلاء.

- يجب أن تكون جميع البراغي موجودة ومشدودة؛ ولا يُسمح بأي مثبتات مفقودة أو إضافية أو فضفاضة.

2. تركيب المكونات الرئيسية

الاتساق هو مفتاح الأداء والامتثال:

يجب أن تتطابق جميع المكونات الرئيسية والهياكل الداخلية مع قوائم المواد وتقارير التفتيش على الشهادات (على سبيل المثال، 5C، ومعايير توفير الطاقة).

يتم فحص الضواغط والمبخرات والمراوح والصواني للتأكد من صحة الطراز وموضع التركيب وقوة عزم الدوران والسلامة الهيكلية.

تم التحقق من أن منصات مكافحة الاهتزاز وتطبيقات المواد المانعة للتسرب وفجوات التخليص تلبي مواصفات التجميع.

3. الأنابيب واللحام وتوجيه المكونات

يتم مراجعة كل خط أنابيب وصمام بعناية:

يجب توجيه صمامات الفحص والملفات اللولبية والمجففات وفقًا لرسومات التصميم؛ ويجب أن تكون نظارات الرؤية مرئية ومحاذية بشكل صحيح.

يجب أن تكون جميع الوصلات الملحومة كاملة وخالية من العيوب، مع حماية النيتروجين أثناء اللحام والتنظيف بعد ذلك.

يجب توجيه أنابيب النحاس بشكل صحيح، دون أي تداخل وبمسافة لا تقل عن 10 مم بين بعضها البعض.

4. تركيب المكونات المحكمة الإغلاق

يتم تثبيت الأجهزة الحساسة للضغط بدقة:

يتم وضع مفاتيح الضغط العالي والمنخفض وتأمينها وفقًا لرسومات قائمة المواد والتخطيط.

يتم تثبيت مفاتيح الضغط التفاضلية مع التحقق من النموذج وضبط الإعدادات.

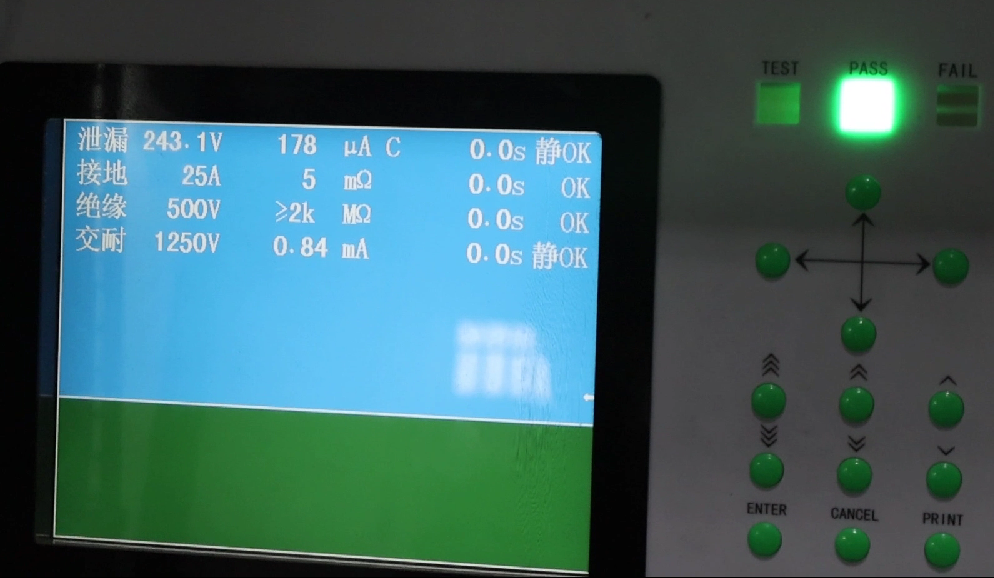

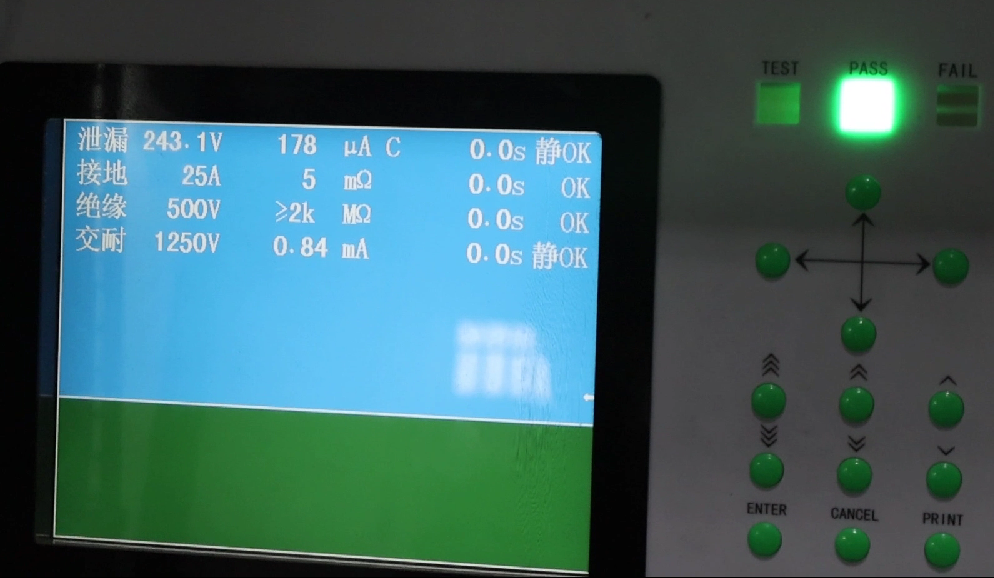

5. اختبار الضغط والغلق

الأداء المقاوم للتسرب أمر إلزامي:

يتم إجراء اختبارات ضغط النيتروجين الأولية والثانوية.

يجب أن تجتاز الوحدات فحوصات إحكام الهواء دون انخفاض الضغط أو التسرب أو تسرب المياه.

يتم إعادة لحام الوحدات الفاشلة وإعادة اختبارها للتأكد من الإغلاق الكامل.

6. تغليف العزل

تعتمد كفاءة الطاقة على العزل المناسب:

يجب أن تكون الأنابيب ملفوفة بالكامل بأكمام عازلة، دون ترك أي فجوات أو تمزقات أو تركيبات فضفاضة.

يجب أن يتوافق العزل في مناطق صندوق التحكم الكهربائي وصينية التصريف مع المعايير الهندسية.

7. تركيب المكونات الثانوية

الأجزاء الأصغر لها نفس الأهمية:

يتم تثبيت أجهزة استشعار درجة الحرارة في الموضع الصحيح ويتم طلائها بمعجون حراري حيث تكون هناك حاجة لذلك.

يجب أن تتوافق السخانات وأجهزة الترطيب مع قائمة المواد (BOM) وأن تكون مؤمنة بإحكام، مع توصيلات مياه محكمة الغلق وبدون تشوه.

يجب أن تكون المرشحات سهلة الوصول إليها، وتتوافق مع قائمة المواد، ويتم تثبيتها بشكل صحيح.

8. مجموعة التحكم الكهربائية

تغطي فحوصات الجودة الكهربائية لدينا التصميم والوظيفة والسلامة:

يجب أن تتوافق الخزانات الكهربائية وجميع المكونات الداخلية مع مواصفات قائمة المواد (BOM).

يتم توجيه الأسلاك بشكل أنيق، ويتم وضع العلامات عليها بوضوح، ويتم توصيلها بإحكام.

يجب أن تكون جميع الأجهزة جاهزة للتشغيل، مع وجود علامات وظيفية وعدم وجود أطراف فضفاضة.

9. تركيب ألواح الأبواب والمكونات

يجب أن يكون الهيكل الخارجي قويًا وسهل الاستخدام:

يجب أن تكون ألواح الأبواب معزولة وناعمة وخالية من العيوب مثل الخدوش أو الانبعاجات.

يجب أن تعمل شاشات التشغيل وأقفال الأبواب بسلاسة، ويجب أن تكون الفجوات الهيكلية ≤ 2 مم.

يجب توصيل الأسلاك الأرضية (PE) بشكل صحيح.

10. وضع العلامات، وملء الغاز، والتنظيف النهائي

تتضمن خطوات ضمان الجودة النهائية ما يلي:

ملء الوحدات الداخلية والخارجية بغاز النيتروجين.

تطبيق ملصقات المنتجات وتحذيرات السلامة الكهربائية ومؤشرات الغاز بدقة وحزم.

إجراء تنظيف كامل داخليًا وخارجيًا - لا يُسمح بالزيت أو الغبار أو الأجسام الغريبة.

تدوير شفرات المروحة يدويًا للتحقق من عدم وجود أصوات غير طبيعية أو تداخل.

الخلاصة: التميز من الداخل إلى الخارج

من تجميع الهيكل إلى اختبار إحكام الإغلاق والتنظيف النهائي، تعكس كل خطوة في عملية إنتاج مكيفات الهواء الدقيقة التزامنا بالحرفية والامتثال ورضا العملاء. سواء كنت تبحث عن موديلات قياسية أو حلول مصممة خصيصًا، تقدم كول نت أنظمة تكييف هواء يمكنك الوثوق بها.

اتصل بفريق Coolnet للحصول على استشارة الخبراء والحلول المخصصة.

بريد إلكتروني: info@coolnetsystem.com

هاتف/واتساب: +86- 18326091011